Following services are provided:

With almost 20 years of experience in laserprofiling, -drilling and -scribing of thick- and thinfilm substrates, we are your professional partner in optimizing your lasered substrate design and requirements in the most cost effective way.

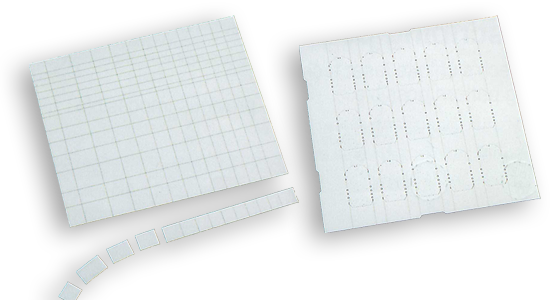

- Accurate scribing of “snapstrates” to customer’s specifications, ranging in sizes from a few mm up to 152,4 mm x 228,6 mm (611 x 9″).

- Precision laserscribed, -profiled and -drilled snapstrates with hole sizes down to 0 0,1 mm for “state of the art” thickfilm printed through hole technology.

- Laserguard – a Laser Tech formulated coating applied to the substrate surface prior to lasering to avoid laserprocess cause ceramic residue on the substrate surface.

- PrimEdge™ and Super PrimEdge™, the Laser Tech developed substrate edge treatment for optimized automatic printing and handling of lasered thick film substrates.

- CAD-datatransfer makes it possible for the customer via e-mail laser@lasertech.dk to transfer the, necessary design data for a safe and fast order turnaround.

- Quick service

Laser Tech’s constantly updated laser technology and laser capacity of 24 laser beams, dedicated to ceramic works, allow us to offer prototypes and pilot runs at cost effective rates within 24-48 hours.

Material and sizes in stock:

Substrates from the major raw material suppliers CoorsTek, CeramTec and Kyocera are available from stock in production quantities.

Generally used for optical thickfilm applications.

Standard available rawmaterial sizes and thicknesses:

- 4,5″ × 4,5″ (114,3 × 114,3 mm) for lasered size 108 × 108 mm

Stock available thicknesses: 0,635 mm and 1,0 mm. Standard camber tolerance 0,3% Other sizes and thicknesses, please contact our sales department.

Generally used for thickfilm applications and isolation purposes.

Standard available rawmaterial sizes and thicknesses:

- 4,5″ × 4,5″ (114,3 × 114,3 mm) for lasered size 108 × 108 mm

Thicknesses: 0,25 – 0,38 – 0,5 – 0,635 – 0,762 – 1,0 – 1,27 – 1,5 – 2,0 mm

- 5,25″ × 4,5″ (133,3 × 114,3 mm) for lasered size 127 × 108 mm

Thicknesses: 0,25 – 0,38 – 0,5 – 0,635 – 0,762 – 1,0 mm

- 6,5″ × 4,5″ (165,1 × 114,3 mm) for lasered size 158 × 108 mm

Thicknesses: 0,25 – 0,38 – 0,5 – 0,635 – 0,762 – 1,0 – 1,27 mm

- 7,5″ × 5,5″ (190,5 × 139,7 mm) for lasered size 184 × 133 mm

Thicknesses: 0,25 – 0,38 – 0,5 – 0,635 – 0,762 – 1,0 mm

- 9,5″ × 6,5″ (241,3 × 165,1 mm) for lasered size 234 × 158 mm

Thicknesses: 0,635 – 1,0 mm

Other sizes and thicknesses, please contact our sales department.

Generally used for thick/thin film applications.

Standard available rawmaterial sizes and thicknesses:

- 4,5″ × 4,5″ (114,3 × 114,3 mm) for lasered size 108 × 108 mm

Thicknesses: 0,25 – 0,38 – 0,635 – 1 mm

Other sizes and thicknesses, please contact our sales department.

Generally used for thinfilm applications.

Standard available rawmaterial sizes and thicknesses:

- 4,5″ × 4,5″ (114,3 × 114,3 mm) for lasered size 108 × 108 mm

Thicknesses: 0,25 – 0,38 – 0,635 – 1,0 mm

Other sizes and thicknesses, please contact our sales department.

ALN (Aluminum Nitride), Forsterite, Bariumtitanate and others are available on request. Please contact our sales department. Laser Tech is not only experienced in lasering of ceramic material, but also in lasercutting none ceramic materials as flexible PCB materials, polyamide and acetate foils. Our experience is available on request.

Camber

Measured between parallel plates in 45° and defined as ex. :s 0,2% ~ 0,051 mm per 25,4 mm in relation to the longest side of the substrate. Laser Tech only stock the premium :s 0,2% cambered substrates for the most commonly used thicknesses and sizes: 0,635 – 0,76 – 1,0 mm (4,5″ × 4,5″ – 6,5″ × 4,5″). Camber tolerance

quaranteed on the following thicknesses is: 0,25 mm :s 0,6%, 0,38 mm :s 0,3%, 0,5 mm :s 0,3%, 1,27 mm :s 0,3%. For tighter camber tolerances please contact our sales department.

The quality

Laser Tech’s quality system, for securing the optimum quality of lasered substrates to the microelectronic industry, has been ISO 9002 certified since 1993, upgraded in 2002 to DS/EN ISO 9001:2000. Laser Tech extended in 2003 the ISO 9001:2000 certification also to be DS/ISO/TS-16949:2002 certified, enabling Laser Tech to be preferred as a supplier to the international automotive industry. The ISO/TS-16949 certification will not only be beneficial to Laser Tech’s automotive customers, but to all our customers.

Quality control

We use quality control to monitor and correct the manufacturing of the products in order to meet our customers quality requirements. SPC (Statistical Process Control) is used wherever possible to help us to get closer to our ultimate goal, a zero-defect production.

Quality policy

It is our policy, by working closely together with our customers, to be able to meet all customer requirements, simplified in the expression “supply the requested product in the right quality on the requested date”. To achieve this requires a total commitment from both staff and manage- ment and it is therefore a natural part of the company spirit of an ongoing commitment to improved quality and service.

Other products and services by Laser Tech

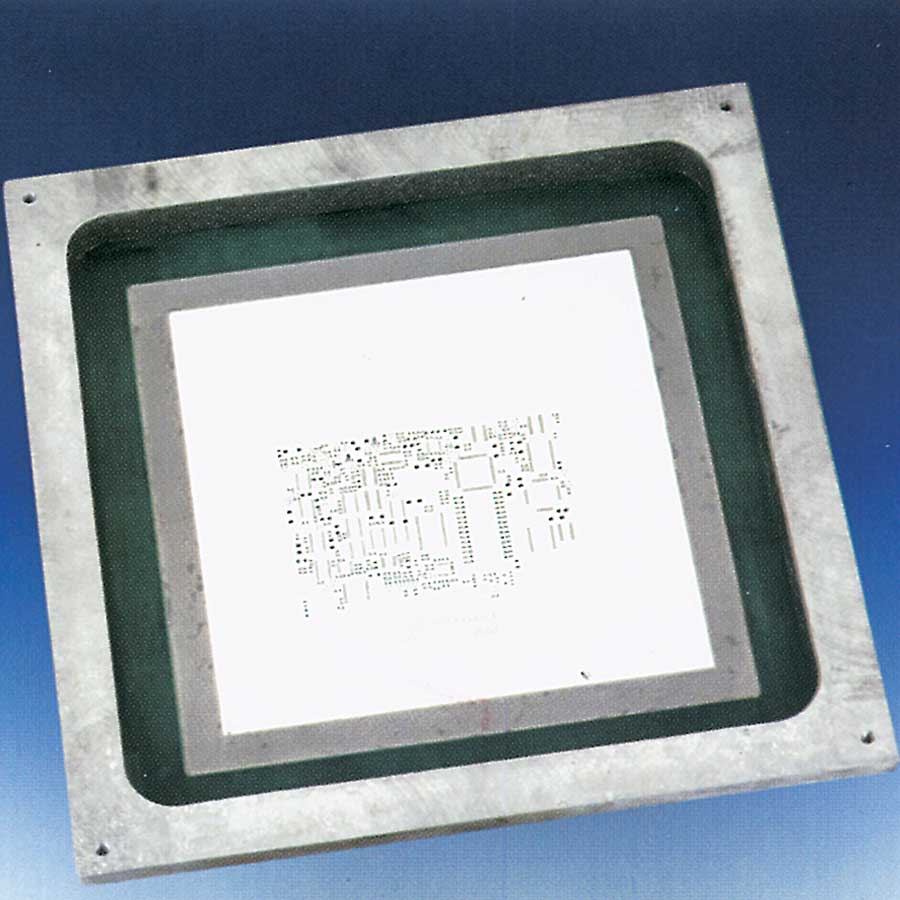

Screen Tech, a division of Laser Tech, with more than15 years experience in manufacturing of precision printing screens for thickfilm printing and SMT-solderpaste printing, offers “state of the art” LaserEtch™ laser cut stainless steel metal mask stencil screens for high yield fine pitch SMT- solderpaste printing, and very specialized stencils for flip chip wafer bumping.

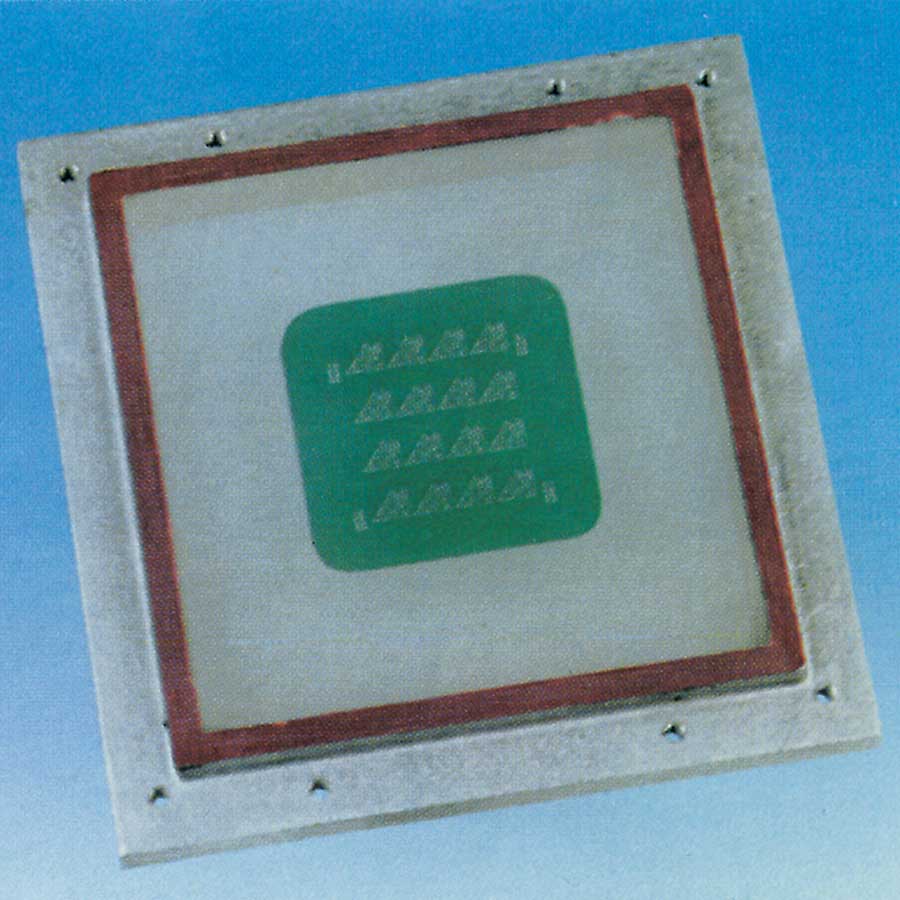

The most modern production facility enables Screen Tech to offer cost effective stainless steel-/polyester mesh screens and metal mask stencil screens at a very short lead time.

For more detailed information about Screen Tech’s products, please contact your Laser Tech representative or the technical sales department.

LaserEtch™ Laser cut stainless steel metalmask stencil screen for fine pitch SMT-solderpaste printing.

Stainless steel mesh screen for thickfilm fineline printing.